3/2 and 4/2 directional poppet valves with solenoid operation

Type M-.SED10...L1X

Features

- Direct operated directional poppet valve with solenoid actuation

- Mounting face as per DIN24 340 A

ISO 4401 and CETOP-RP 121H

- Closed port is leak-free isolated

- keep switch flexibility under high pressure

- Pressure-tight chamber does not need to be opened for a change of

the coil

- Solenoid coil can be rotated through 90°

- With concealed manual override, optional

Function and configuration

·Type M-SED10 3/2 directional poppet valve

Directional valves of the type SED are direct operated directional

poppet valves with solenoid actuation.

They control the start, stop and direction of flow.

The directional poppet valves consist of housing (1), the solenoid

(2), the valve seat (7) and (11) and the control spool (4).

The manual override (6) allows for the switching of the valve

without solenoid energization.

General principle (3/2 directional poppet valve):

The initial position of the valve (normally open "UK" or normally

closed "CK") is determined by the arrangement of the spring (5).

The chamber (3) behind the control spool(4) is connected to port P

and sealed against port T. Thus, the valve is pressure compensated

in relation to the actuating forces (solenoid and spring).

By means of the control spool (4),the port P,A and T can be loaded

with maximum operating pressure (350bar) and the flow can be

directed in both directions (see symbols).

In the initial position, the control spool (4) is pressed onto the

seat (11) by the spring (5), in spool position, it is pressed onto

the seat (7) by the solenoid (2). The flow is blocked.

·Type M-4SED10 4/2 directional poppet valve

With a sand with plate, the Plus-1plate, under the 3/2 directional

poppet valves, the function of a 4/2 directional poppet valve is

achieved.

1). Initial position:

the main valve is not actuated. The spring(5)holds the control

spool(4)on the seat(11).Port P is blocked and A is connected to T.

Apart from that, one control line is connected from A to the large

area of the control spool(8), which is thus unloaded to the tank.

The pressure applied via P now pushes the ball(9) onto the

seat(10). Now, P is connected to B, and A to T.

2). Transition position:

When the main valve is actuated, the control spool(4) is shifted

against the spring(5) and pressed onto the seat(7). During this,

port T is blocked, P, A, and B are briefly connected to each other.

3). Spool position:

P is connected to A.As the pump pressure acts via A on the large

area of the control spool (8), the ball (9) is pressed onto the

seat (12). Thus, B is connected to T, and P to A. The ball (9) in

the Plus-1 plate has a "positive spool overlap".

·Throttle insert:

The use of a throttle insert is required, if, due to the operating

conditions, flows are to be expected during the switching

procedure, which are higher than the started maximum performance

limits of the valve.

The throttle is inserted into port P of the valve.

·Cartridge check valve:

The cartridge check valve allows free flow from P to A and provides

leak-free closed from A to P.

The cartridge check valve is inserted into port P of the valve.

Spool symbols

Specification

Technical data

| Installation position | Optional |

| Environment temperature | ℃ | -30 to +50 (NBR seal) |

| -20 to +50 (FKM seal) |

| Weight | Two tee Solenoidic directional valve | Kg | 2.6 |

| Two four-way Solenoidic directional valve | Kg | 3.9 |

| Max operation pressure | bar | 350 |

| Max flow | L/min | 40 |

| Hydraulic fluid | Mineral oil suitable for NBR and FKM seal |

| Phosphate ester for FKM seal |

| Fluid temperature range | ℃ | -30 to +80 (NBR seal) |

| -20 to +80 (FKM seal) |

| Viscosity range | mm2/s | 2.8 to 500 |

| Degree of contamination | Maximum permissible degree of fluid contamination:Class 9. NAS 1638

or 20/18/15, ISO4406 |

Electrical data

| Voltage type | DC | AC+ rectifier |

| Voltage version | V | 12, 24, 110, 205, 220 | 110,220(only possible via Z5 rectifier) |

| Permissible voltage(deviation) | % | +10~-15 |

| Input power | W | 30 |

| Continuous power-on time | Continuous |

| Switching time to ISO 6403 |

| Pressure bar | Flow L/min | DC solenoid | AC + rectifier |

| On/ms (without oil tank pressure) | Off/ms | On/ms (without oil tank pressure) | Off/ms |

| UK | CK | D | Y | UK, CK | D, Y | UK | CK | D | Y | UK, CK | D, Y |

| 70 | 40 | 40 | 30 | 40 | 35 | 10 | 10 | 35 | 30 | 40 | 35 | 40 | 40 |

| 140 | 40 | 40 | 30 | 40 | 35 | 10 | 10 | 40 | 30 | 40 | 35 | 40 | 40 |

| 210 | 40 | 45 | 35 | 45 | 35 | 10 | 10 | 45 | 35 | 45 | 35 | 40 | 40 |

| 280 | 40 | 45 | 35 | 45 | 35 | 10 | 10 | 45 | 35 | 45 | 35 | 40 | 40 |

| 315 | 40 | 50 | 35 | 50 | 35 | 10 | 10 | 50 | 40 | 50 | 35 | 40 | 40 |

| 350 | 40 | 50 | 45 | 50 | 45 | 10 | 10 | 50 | 45 | 50 | 45 | 40 | 40 |

| Note: The switching types relate to a flow of P to A and A to T. With

reversed flows deviations are possible. |

| Switching frequency | Cycles/h | to 15000 |

| IP rating as per DIN 40050 | IP65 |

| Max coil temperature | ℃ | +150 |

Note: for electrical connection, protective wire (PE) shall be earthed

as required.

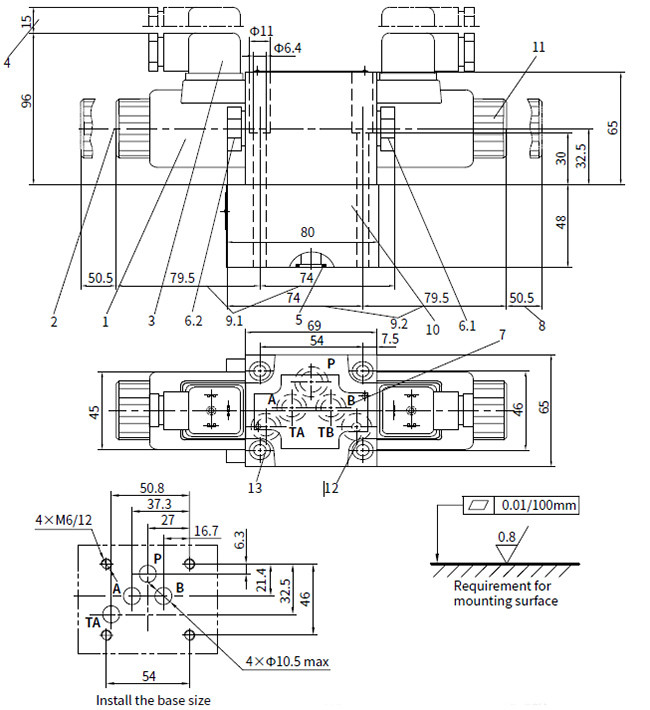

Unit dimensions

·M-3SED10 -L1X/...solenoid directional poppet valve

1 Solenoid

2 Manual override

3 Plug-in connector to DIN 43650 (rotatable 90º)

4 Space required to remove the Plug-in connector

5 O-rings 12×2 for ports A,B,TA,TB

O-rings 14×2 for port P

6.1 Plug for M-3SED10UK-L1X/

6.2 Plug for M-3SED10CK-L1X/

7 Name plate

8 Space required to remove the coil

9.1 Total length of M-3SED10UK-L1X/

9.2 Total length of M-3SED10CK-L1X/

10 Securing nut tighting torque MA = 4Nm

11 Ports B and TB are a blind counter bore

12 Valve fixing screws

Internal hexagon screw: M6×40 GB/T 70.1-10.9,

tighting torque MA = 15.5 Nm

It must be ordered separately, if connection plate is needed. Type:

G 66/01 (G 3/8), G 66/02 (M18×1.5)

G 67/01 (G 1/2), G 67/02 (M22×1.5)

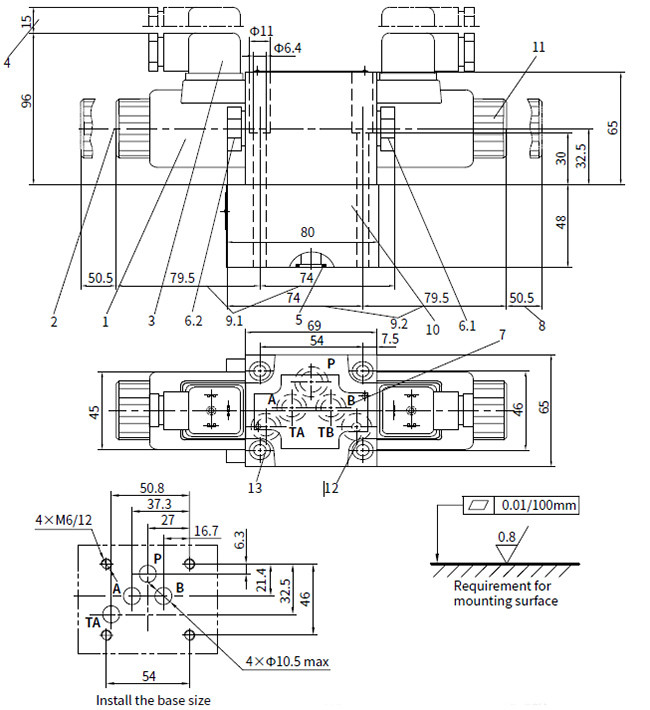

·M-4SED10 -L1X/...solenoid directional poppet valve

1 Solenoid

2 Manual override

3 Plug-in connector to DIN 43650 (rotatable 90º)

4 Space required to remove the Plug-in connector

5 O-rings 12×2 for ports A,B,TA,TB

O-rings 14×2 for port P

6.1 Plug for M-4SED10D-L1X/

6.2 Plug for M-4SED10Y-L1X/

7 Name plate

8 Space required to remove the coil

9.1 Total length of M-4SED10D-L1X

9.2 Total length of M-4SED10Y-L1X

10 Plus-1 Plate

11 Securing nut tighting torque MA = 4Nm

12 Port TB is a blind counter bore

13 Valve fixing screws

Internal hexagon screw: M6×40 GB/T 70.1-10.9,

tighting torque MA = 15.5 Nm

It must be ordered separately, if connection plate is needed. Type:

G 66/01 (G 3/8), G 66/02 (M18×1.5)

G 67/01 (G 1/2), G 67/02 (M22×1.5)