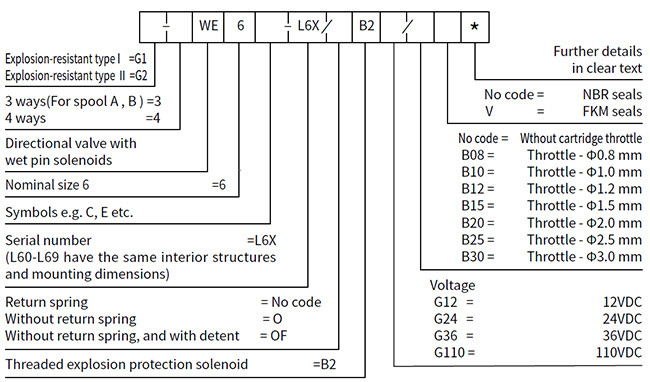

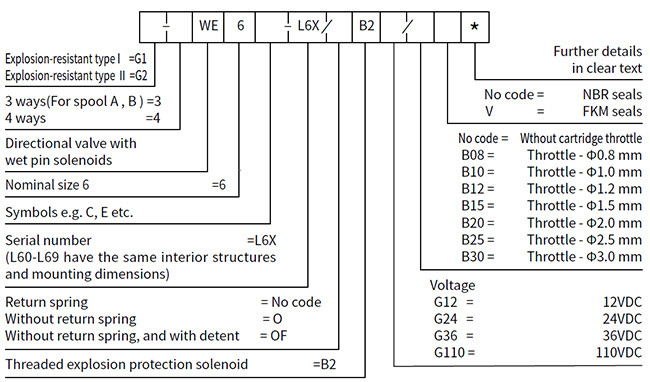

4/3, 4/2 and 3/2 explosion-proof solenoid directional valve

Type G...WE6...L6X

Features

-Directly operated type explosion protection directional valve is

used as the standard type

-DIN24 340 A type on the mounting surface ISO 4401 and CETOP-RP

121H

-Wet-type DC explosion protection solenoid

-90° rotatable explosion protection solenoid

-Pressure-tight chamber does not need to be opened when coil is to

be replaced

Function and configuration

GWE type directional control valve is the directional valve of

explosion protection solenoid used to control start, stop and flow

direction of oil fluid.

The directional control valves consist of housing (1), one or two

solenoids (2), the control spool(3), and one or two return springs

(4).

In the de-energized condition the control spool (3) is held in the

neutral or initial position by means of return springs (4) (except

for pulse spools). The control spool (3) is actuated via wet pin

solenoids (2).

To guarantee satisfactory operation care should be taken to ensure

that the solenoid pressure chamber is filled with oil.

The control spool(3) is moved to the expected position by

solenoid(2) and pushing rod(5), and this gives free flow from P to

A and B to T or P to B and A to T.

When the explosion protection solenoid(2) is powered off, control

valve element (3) is pushed to the initial position by reset spring

(4).

Type G4WE6...L6X/OB2...

(limited to functions A, C and D).

This type contains 2 switching positions and 2 directional control

valves without locating mechanism explosion protection solenoid.

Type G4WE6...L6X/OFB2... pulse valve

(limited to functions A, C and D).

It contains 2 switching positions, 2 explosion protection solenoids

and 1 directional control valve with locating mechanism. 2

switching positions are fixed separately, so it is unnecessary to

continuously electrify explosion protection solenoid.

Cartridge throttle

The cartridge throttle is necessary since the actual flow may be

larger than the performance limits of the valve during switching

process. This cartridge throttle is inserted in the P channel of

the directional control valve.

Specifications

Note: G1 Explosion protection grade EX d Ⅰ Mb; G2 Explosion protection

grade EX d Ⅱ C T4 Gb

Spool symbols

Technical data

| Fixing position | Optional |

| Environment temperature range | ℃ | -30 to +50 (NBR seal) |

| -20 to +50 (FKM seal) |

| Weight | Single solenoid | kg | 2.6 |

| Double solenoids | kg | 4.3 |

| Max.operating pressure | Port P, A, B | bar | 350 |

| Port T | bar | 210 |

| when the operating pressure exceeds the permission value, spool

symbol A and B must make the port T for draining |

| Max. flow-rate | L/min | 80 |

| Flow cross section (switching neutral position ) | VersionQ | mm2 | About 6% of nominal area |

| VersionW | mm2 | About 3% of nominal area |

| Fluid | Mineral oil suitable for NBR and FKM seal |

| Phosphate ester for FKM seal |

| Fluid temperature range | ℃ | -30 to +80 (NBR seal) |

| -20 to +80 (FKM seal) |

| Viscosity range | mm2/s | 2.8 to 500 |

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS

1638 or 20/18/15, ISO4406 |

Electrical data

| Type of voltage | DC |

| Available voltage | V | 12, 24, 36, 110 |

| Permissible voltage (deviation) | % | -15 to +10 |

| Input power | W | 30 |

| Operation mode of solenoid | Continuous working |

| Switched time Accord with ISO 6403 | ON | ms | 25 to 45 |

| OFF | ms | 10 to 25 |

| Switched frequency | times/h | To 15000 |

| Max. coils temperature | ℃ | +150 |

Caution: with electrical connections the protective conductor (PE) must be

connected according to the relevant regulations.

Unit dimensions (Dimensions in mm)

1 Explosion protection solenoid

2 Copper nameplate

3 R-ring 9.81×1.5×1.78 or O-ring 9.25×1.78

4 End cap used for 1 electro solenoid valve

5 Dimensions of 3-position valve

6 Dimensions of 2-position valve, solenoids at end A

7 Dimensions of 2-position valve, solenoids at end B

8 Valve fixing screws:

M5×50 GB/T70.1-10.9

Tightening torque, MA=8.9Nm must be ordered separately.

It must be ordered separately, if connection plate is needed .Type:

G341/01(G1/4); G341/02(M14×1.5)

G342/01(G3/8); G342/02(M18×1.5)

G502/01(G1/2); G502/02(M22×1.5)