2/2, 3/2 and 4/2 directional poppet valve with solenoid actuation

Type M-.SEW6...L3X

Features

- Direct-acting solenoid direction shut-off valve

- Mounting face as per DIN24 340 A

ISO 4401 and CETOP-RP 121H

- Free of leakage

- Switching flexibility in high-pressure state

- Replace the coil, can take pressure operation

- Solenoid coil can rotate for 90 degrees

- Manual emergency operation available

Function and configuration

M-SEW6 direction valve is a solenoid shut-off directional poppet

valve for control oil opening, stop and flow direction.

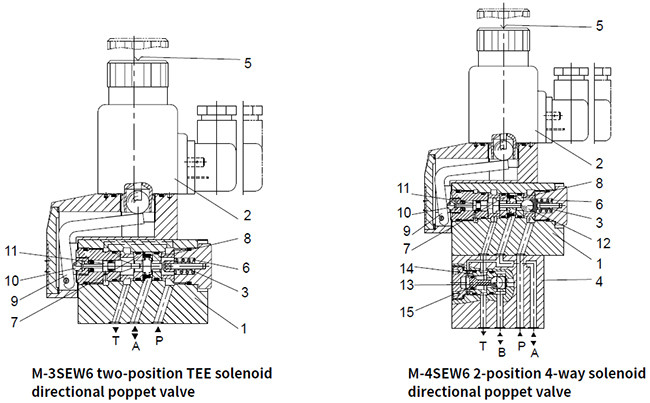

Two-position TEE solenoid directional poppet valve consists of

valve body (1), Solenoid (2), and valve element (3). Connect a

superposition plate below the two-position TEE solenoid directional

poppet valve to connect valve body (4), it becomes into

two-position four-way direction poppet valve. The manual emergency

button (5) can be used to operate the valve when the Solenoid is

not powered on.

· M-3SEW6 two-position TEE solenoid directional poppet valve

1). Initial position:

when the Solenoid is not energized, pretention of spring (6) keeps

valve element (3) on valve seat (7) on the left, so that oil port P

is connected to A and oil port T is closed.

2). Switching position:

after the Solenoid is energized, through angular lever (9) and ball

(10), the force of Solenoid (2) acts on push rod (11) of the

two-side seal, thus to push valve element (3) and maintain it on

right valve seat (8), causing oil port P closed and oil port A

connected to port T. Since push rod (11) and valve element (3),

acted by the inlet pressure, is in a balance state of axial

hydraulic pressure, the valve can be used when pressure is up to

420bar.

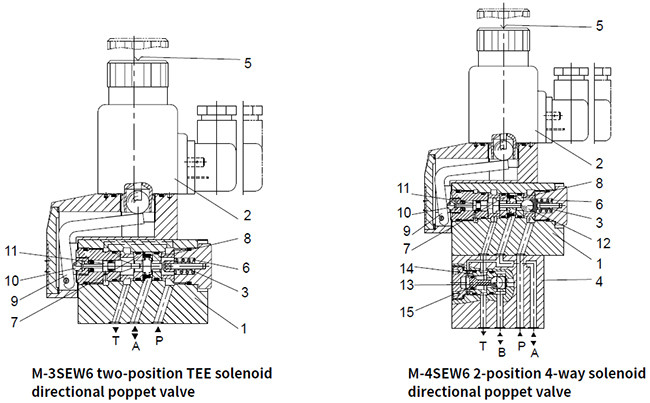

· M-4SEW6 2-position 4-way solenoid directional poppet valve

1). Initial position:

when the Solenoid is not energized, pretention of spring (6) keeps

valve element (12) on valve seat (8) on the right, oil port P is

closed and port A connected to T; pressure oil supplied from oil

port P push steel ball (13) to valve seat (14), upon which oil port

P is connected to B and A connected to T; besides, a control oil

line is connected from oil port A acts on the big area of control

piston (15), which can be used for unloading to oil tank.

2). Switching position:

after the Solenoid is energized, oil port P is connected to A;

pressure oil from the pump goes through the control oil line

connected from port A and acts on the big area of control piston

(15); steel ball (13) is pushed to the other side of valve seat

(14), thus oil port P is connected to A and B connected to T.

· Cartridge restriction choke (model M-.SEW6.L3X/.../B...)

To restrict flow through the valve, a restriction choke can be

installed.

Restriction choke is installed on port P.

· Cartridge type one-way valve (model M-.SEW6.L3X/.../P)

Cartridge type one-way valve allows oil flow in from port P and it

is closed for reverse flowing.

One-way valve installed on port P.

Spool symbols

Specification

Technical data

| Installation position | Optional |

| Environment temperature | ℃ | -30 to +50 (NBR seal) |

| -20 to +50 (FKM seal) |

| Weight | Two two-way Solenoidic directional valve | Kg | 1.5 |

| Two three-way Solenoidic directional valve | Kg | 1.5 |

| Two four-way Solenoidic directional valve | Kg | 2.3 |

| Max operation pressure | Port P, A, B | bar | 420 |

| Port T | 100 |

| Max flow | L/min | 25 |

| Fluid | Mineral oil suitable for NBR and FKM seal |

| Phosphate ester for FKM seal |

| Fluid temperature range | ℃ | -30 to +50 (NBR seal) |

| -20 to +50 (FKM seal) |

| Viscosity range | mm2/s | 2.8 to 500 |

| Degree of contamination | Maximum permissible degree of fluid contamination: Class 9. NAS

1638 or 20/18/15, ISO4406 |

Electrical data

| Voltage type | DC | AC |

| Available voltage | V | 12, 24, 110, 205, 220 | 110, 220 (Only by Z5 rectifier plug ) |

| Allowed voltage (deviation) | % | +10~-15 |

| Required power | W | 30 |

| Continuous power-on time | % | 100 |

| Switching time in compliance with ISO 6403 |

| Pressure bar | Flow L/min | DC | AC50HZ |

| on/ms (without oil tank pressure) | off/ms | on/ms (without oil tank pressure) | off/ms |

| U | C | D | Y | U, C | D, Y | U | C | D | Y | U, C | D, Y |

| 140 | 25 | 25 | 30 | 25 | 30 | 10 | 10 | 30 | 40 | 30 | 40 | 35 | 35 |

| 280 | 25 | 25 | 30 | 25 | 30 | 10 | 10 | 35 | 45 | 35 | 45 | 40 | 40 |

| 320 | 25 | 25 | 35 | 25 | 35 | 10 | 10 | 35 | 50 | 35 | 50 | 40 | 40 |

| 420 | 25 | 25 | 35 | 25 | 35 | 10 | 10 | 40 | 50 | 40 | 50 | 50 | 50 |

| Switching frequency | Time/h | Up to 15000 |

| IP rating as per DIN 40050 | IP65 |

| Max coil temperature | ℃ | +150 |

Note: for electrical connection, protective wire shall be earthed as

required.

Unit dimensions

·2-position 2-way, 2-position 3-way solenoid directional poppet

valve

1 Solenoid

2 Manual emergency button

3 Plug as per DIN43650 (can rotate for 90 degrees)

4 Remove space needed for Solenoid coil.

5 Lock nut, tightening torque MA=4Nm

6 Remove space

7 Name plate.

8. Oil port A and B use O ring 9.25×1.78, P uses O-ring 10×2

9. Valve securing screw: M5×45 GB/T70.1- class 10.9, Tightening

torque MA=8.9Nm

10 2-position 2-way directional valve has oil port A and B which

are blind holes;

3/2 directional poppet valve has oil port A and B which are blind

holes.

·2-position 4-way solenoid directional poppet valve

1 Solenoid

2 Manual emergency button

3 Plug as per DIN43650 (can rotate for 90 degrees)

4 Remove space needed for Solenoid coil.

5 Lock nut, tightening torque MA=4Nm

6 Remove space

7 Name plate.

8 Connecting valve body

9 Oil port A and B use O ring 9.25×1.78, P uses O-ring 10×2

10 Valve securing screw hole, M5×90 GB/T70.1-10.9, Tightening

torque MA=8.9Nm